Learning to drive a truck with an 18-speed transmission can seem like a daunting task, especially for new drivers. Having a basic understanding of the gears and switches can give you a leg up before CDL school, and with some practice you'll master shifting and floating gears. Correctly and efficiently shifting gears will extend the life of your truck, lower your cost per mile and save you lots of money in fuel and maintenance costs over time.

In this blog post, we will discuss the basics of an 18-speed transmission, providing helpful tips to ease your journey.

Understanding the 18-Speed Transmission

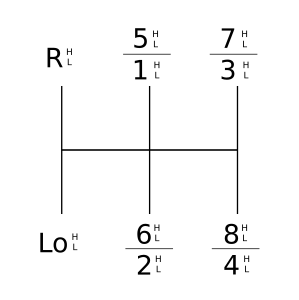

An 18-speed transmission has 18 forward gears and 2 reverse gears. These gears are organized into a standard H configuration that is usually printed on the gearshift knob.

In an 18-speed transmission, the main gears are shifted using the shift lever, while the splitter and range gears are controlled by two switches (splitter switch and range switch) on the gearshift knob.

Range Selector

The range selector is generally on the front of the gear shift lever. You'll move it with your index or middle finger. You can shift into gears Lo-4 with it in the down position. Access gears 5-8 by flipping it to the up position. You'll only flip the range selector when switching from 4th to 5th gear and downshifting from 5th back to 4th gear.

Splitter

The splitter switch is on the left side of the gear shift knob and you'll flip it with your thumb. In 18-speed vehicles it will be gray - red in a 13-speed and blue in a 15-speed - and it is used to select the high or low setting of the gear you're in.

Splitting gears isn't always necessary. Lots of drivers never split gears except top gear unless they are hauling a heavy load where they need extra torque on the low end to get moving.

When splitting gears while upshifting, you'll start in the low setting. You'll release the throttle to switch into high then give it more throttle. When you shift into the next gear, you'll have to switch it back to low while in neutral. Do the opposite when downshifting - split back down to low, then switch to high before shifting into the lower gear.

Understanding the Clutch

At its most basic, the clutch is a mechanical device that engages and disengages the power transmission. It controls the connection between the shaft coming from the engine and the shafts which drive the wheels.

Pressing the clutch all the way to the floor engages the clutch brake, which stops the transmission gears from turning so you can get into your starting gear. You'll only engage the clutch brake when shifting into gear from a complete stop.

For shifting into higher gears, or downshifting, you'll only press the clutch pedal partway down. Pressing the clutch too far will start engaging the clutch brake and slow down the transmission gears and make for a pretty rough shift.

Double-Clutching

When disengaging the clutch to shift gears, you'll need to pump the clutch slightly to shift into neutral, release the clutch, then pump it again to shift into the next gear. Each truck is different of course, so the sweet spot may only be an inch in one truck but halfway to the floor in another.

It should be noted that most professional drivers with experience don't use the clutch at all after getting into gear. They will "float the gears", which involves matching engine rpms to transmission rpms to ensure a smooth shift into higher or lower gear. We'll get into that topic later in the article.

Learning to properly use the clutch to shift will be how you start out learning, and you will likely have to display mastery of it to get your CDL.

Downshifting Safely

Downshifting is mostly the same as shifting up, but there is an extra step to consider. You may need to press the throttle slightly while in neutral to match your engine and transmission RPMs before shifting into the lower gear. This will help prevent transmission wear and ensure smoother shifts.

When traveling downhill, trying to downshift can create dangerous situations such as a truck rolling over around bends or a runaway truck on a steep grade. Always watch for grade signs posted to help you prepare for a dowainnhill. Best practice is to slow down and get into a lower gear before you start down the grade (one gear lower than it took to climb the hill). Use the jake brake to help control your speed and leave as much space in front of you as you can to have room for correction.

Practice Shifting an 18-Speed Transmission

Before you start practicing gear shifting, ensure that your truck is parked on a level surface with the parking brake engaged. Make sure to familiarize yourself with the gearshift pattern and the location of the switches on the gearshift knob.

How to Shift an 18-Speed Transmission

Follow these steps to start from a complete stop and shift through your gears using the clutch:

-

Starting from Neutral: With the engine running, ensure the shift lever is in the neutral position, the range selector is in the low range (down), and the splitter switch is in low (back). Disengage the clutch by pressing the clutch pedal all the way down.

-

Selecting starting gear: You will only need to start out in Lo gear if you're hauling a very heavy load or starting on a steep incline. You can start with any gear from Lo to 4th gear - heavier load, lower starting gear - and the engine will have enough torque to get the vehicle moving. For practicing, go ahead ans start in 1st gear.

-

Shifting into starting gear: With the clutch still disengaged, move the shift lever to the desired main gear. Slowly but completely release the clutch. Then press the throttle to accelerate.

-

Using the Splitter Gears: If you are splitting the gear, release the throttle and flip the switch forward into high. Then press the throttle to accelerate.

- Shifting into the next main gear: Release the throttle and press the clutch in about halfway. Flip the splitter switch back to low if you are splitting gears. Move the shifter into neutral. Release the clutch. Press the clutch about halfway again and move the shifter into the next gear. Give it some throttle to accelerate.

-

Shifting to High Range: When you are in 4th gear, you'll need to flip the range selector switch up to the high range while in neutral, before shifting into 5th gear.

-

Downshifting: To downshift, simply follow the same process as upshifting, but in reverse order. Be sure to rev-match by briefly applying pressure to the accelerator as you release the clutch in the lower gear. Remember to flip the range selector down into low between 5th gear and 4th gear. If you're splitting gears, flip back into high before shifting into the lower gear.

Floating Gears on an 18-Speed Transmission

Floating gears refers to a method of shifting gears on a manual transmission without using the clutch. The goal is to match the speed of the transmission's input shaft (driven by the engine) with the speed of the transmission's output shaft (driving the wheels) for the gear you want to engage. When the speeds are matched, the gear can be smoothly engaged without grinding.

Floating gears is a common practice among truck drivers, especially those driving heavy-duty trucks with many gears, such as an 18-speed transmission. Here is a step-by-step guide on how floating gears work:

-

Accelerate: Start by accelerating in your current gear until your engine RPM reaches the desired level. The exact RPM will depend on your vehicle, your load, and the gear you're in, but it might be around 1500-2000 RPM.

-

Lift off the Accelerator: Let off the accelerator to allow the engine RPM to start falling. This reduces the torque being transmitted through the gearbox, making it easier to shift.

-

Shift to Neutral: Move the gear shift lever to the neutral position. You should be able to do this without using the clutch if you've correctly let off the accelerator.

-

Match RPM for Next Gear: If you're upshifting (going to a higher gear), you'll need to let the engine RPM fall to the correct level for the next gear. If you're downshifting (going to a lower gear), you'll need to increase the engine RPM. You can do this by "blipping" the throttle—quickly pressing and releasing the accelerator pedal. The goal is to match the engine speed with the speed that the input shaft of the transmission needs to be for the next gear.

-

Engage Next Gear: Once the engine RPM is correct for the next gear, you can move the gear shift lever into position for the next gear. If your engine RPM is matched correctly, it should slip into gear without grinding.

-

Resume Acceleration: Once the gear is engaged, you can resume accelerating.

Repeat this process for each gear shift. Remember, this takes practice, and the exact RPM for each gear will depend on many factors, including the specific design of your transmission, the load you're carrying, the grade of the road, and more.

While floating gears can be an efficient way to shift in heavy-duty vehicles, it's essential to know that it requires practice and understanding of your vehicle's operation. It can also increase wear on your transmission if done improperly. For beginners, using the clutch while shifting is recommended as it's easier and less likely to cause damage. Always refer to your vehicle's owner manual for guidance or seek professional training.