Most modern trucks and trailers run air suspensions for one simple reason: they make the job easier. Air-ride smooths out the road, keeps ride height consistent under changing loads, and reduces the pounding that beats up drivers, freight, and equipment over time.

But “air-ride” gets talked about like it’s one single part. It isn’t. It’s a system that uses air pressure to carry weight and manage ride height. When it’s working right, you barely think about it. When it’s not, you’ll notice sagging, uneven stance, rough ride, and more time spent chasing problems you didn’t plan for.

This guide explains what an air-ride suspension is, how it works on trucks and trailers, what it’s good at, what it costs to maintain, and how it connects to one of the biggest pain points in trucking: avoiding overweight surprises before you roll.

What Is An Air-Ride Suspension?

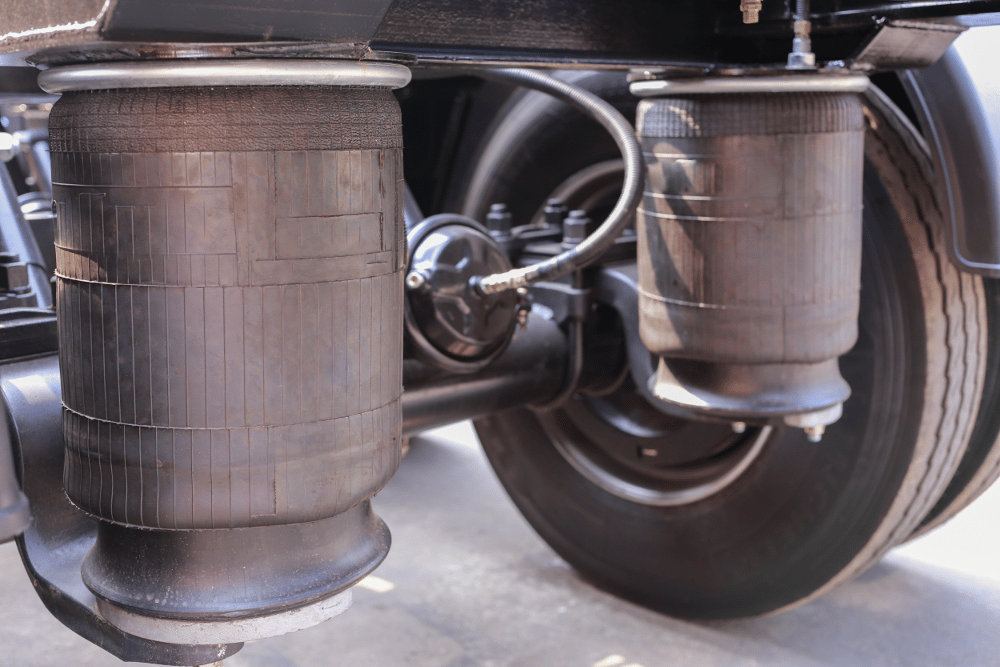

An air-ride suspension replaces traditional steel springs with air-filled rubber bellows (often called air springs or air bags). Instead of metal springs carrying the load, air pressure carries the load.

That difference matters because air pressure is adjustable. As the truck or trailer gets loaded, the suspension compresses and the system increases air pressure to maintain proper ride height. When weight comes off, the system releases air to bring the ride height back down. The goal is a consistent stance, stable handling, and a smoother ride across different load conditions.

In trucking, air-ride is common on over-the-road tractors and many freight trailers because it reduces shock and vibration. That helps drivers stay comfortable and helps freight arrive in better condition. It also helps fleets keep equipment in service longer by reducing constant harsh impacts.

Air-Ride Suspension Vs Helper Air Bags

A lot of people say “air suspension” and mean different things. In the real world, there’s a difference between true air-ride and helper bags.

True air-ride suspension means the air springs are the primary suspension. They do the main job of supporting the vehicle. This is what you’ll see on many semis and trailers built for smoother ride quality.

Helper air bags are add-ons used to assist a spring suspension. They’re common in pickups and some vocational setups where extra leveling is needed under heavy tongue weight or payload, but they don’t replace the main suspension system.

For fleets, this distinction matters because maintenance, ride behavior, and how pressure relates to load can look different depending on whether air springs are the main suspension or just assisting it.

How Air-Ride Suspension Works

Air-ride suspension is built around one operational goal: maintain ride height and absorb shock while the vehicle is moving and while load conditions change.

When weight increases, the frame wants to drop closer to the axles. Air-ride responds by increasing air pressure in the air springs to lift the vehicle back to a set ride height. When weight decreases, the frame rises and the system releases air to settle it back down.

That leveling effect is what drivers and fleet managers usually describe as “it rides steady” or “it stays level under load.” In trucking, stability and consistency matter because unpredictable ride height affects handling, ride quality, and axle load behavior.

Key Components And What They Do

Air-ride isn’t complicated once you understand the parts and the job each one performs.

Air springs are the rubber bellows that inflate and deflate to carry weight and cushion movement. Air supply comes from the vehicle’s air system or an integrated compressor setup depending on the application. Air lines and fittings move air to the springs and valves, and they’re also the most common source of slow leaks.

Height control valves control air flow. In many truck and trailer setups, the leveling valve is the key piece that helps keep ride height consistent as the load changes. Some systems are mechanical and straightforward. Others use height sensors and electronic controls that manage ride height more precisely.

Many setups also use an air reservoir or stored air volume to make adjustments smoother and quicker. In the real world, the “feel” of air-ride comes down to how well these components work together and how well the system is maintained.

What Self-Leveling Really Means

Self-leveling doesn’t mean the truck magically fixes everything. It means the suspension is actively managing ride height to stay within a target range.

When it’s working properly, you don’t get big changes in stance from load to load. The vehicle rides more consistently, and the suspension stays in the range it was designed to operate in.

For operations, that consistency helps in a few ways. It improves stability on the road, reduces harsh impacts into the frame and freight, and makes the loading process more predictable. It also helps avoid the “something feels off” situation where a driver has to guess if the load is balanced or if the trailer is sitting wrong before pulling out.

Air-Ride Suspension Vs Leaf Spring Suspension

Leaf springs are simple and tough. Air-ride is smoother and more controlled. That’s the basic tradeoff.

Leaf spring suspension is often cheaper to maintain and has fewer components that can leak or malfunction. Many fleets like it for harsh environments, job sites, and operations where rugged simplicity is the priority such as hauling timber out of a mountain.

Air-ride usually wins on ride quality and load leveling. It reduces vibration and shock, which can help with driver fatigue and freight protection. It also handles changing loads in a controlled way by maintaining ride height rather than letting the suspension “settle” and stay there.

There’s no universal winner. The right choice depends on your duty cycle and what problems you’re trying to reduce. If your fleet runs long miles with varying loads and cares about cargo protection, air-ride is often worth it. If you live in rough conditions and want fewer air components to manage, leaf springs may fit better.

Benefits Of Air-Ride Suspension For Fleets

Air-ride is popular because trucking is hard on everything. The road beats on the truck. The truck beats on the freight. The driver absorbs the rest.

Air-ride takes a big chunk of that punishment out of the system by smoothing impacts and keeping the vehicle level. Over time, that translates into less fatigue, fewer “mystery” issues caused by constant vibration, and fewer freight problems that start with harsh riding conditions.

Here are the practical benefits fleets usually care about most:

- Smoother ride quality that reduces vibration

- Better load leveling as freight weight changes

- Improved cargo protection for sensitive loads

That list is short on purpose. Air-ride doesn’t need hype. The real value is that it makes daily operations more consistent, especially when you’re hauling freight that can’t take a beating.

Drawbacks And Tradeoffs

Air-ride isn’t free. It adds parts, and parts fail.

The biggest tradeoff is complexity. Air springs, lines, fittings, valves, and sometimes sensors and control modules create more failure points than a basic spring setup. When a spring system has an issue, it’s often obvious. When an air system has an issue, it can leak slowly for weeks before it becomes downtime.

Air-ride can also cost more to repair. Diagnosing air leaks, replacing air bags, and fixing height control issues may take more time than basic suspension work. For fleets, the best approach is preventative attention: catch leaks early, keep the system dry and healthy, and avoid letting small problems turn into big ones.

What Failure Looks Like In Real Operations

Air-ride problems usually show up in patterns. Fleets don’t always see a total failure on day one. They see nuisance issues that grow.

Common signs include sagging overnight, uneven stance side-to-side, slow leveling after loading, rougher ride than normal, or air cycling more often than it should. Drivers may notice that the trailer sits differently from one stop to the next, or that the truck feels less stable than it used to.

If you’re trying to avoid downtime, treat those symptoms like early warning signs. Air-ride issues rarely “fix themselves.” They usually get worse until the leak is found or the component is replaced.

Common Air-Ride Suspension Problems And What To Check First

Most air-ride problems fall into a handful of categories. If you’re troubleshooting, start with the basics before chasing complicated explanations.

Air leaks are the number one issue. Leaks can come from damaged air bags, cracked lines, loose fittings, or valve issues. Even small leaks matter because they force the system to work harder and can change ride behavior over time.

Moisture is another common problem. Air systems don’t like water. Moisture can cause corrosion, sticky valve behavior, and freezing issues in cold conditions. If a fleet sees repeat air system problems, moisture management is often part of the solution.

Leveling valve issues are a big one, especially when you see inconsistent ride height after loading. If the valve is sticking, out of adjustment, or damaged, the system can’t maintain the ride height it’s supposed to.

Finally, sometimes the “rough ride” complaint isn’t the air-ride itself. Worn shocks, bushings, or suspension hardware can make an air-ride system feel harsh even if the air side is working properly.

If you want a tight “check-first” list for the yard, keep it simple:

- Look and listen for air leaks at bags, lines, and fittings

- Check for uneven ride height under similar load conditions

- Pay attention to frequent air cycling or slow leveling behavior

That’s enough to catch most problems early without overcomplicating the process.

How To Tell If Your Truck Or Trailer Has Air-Ride

Most drivers can spot air-ride once they know what to look for.

Air-ride setups typically have rubber air bags near the axle group with air lines feeding into them. Many trailers will have a height control linkage near the suspension area. If you see air bags instead of steel leaf spring packs doing the main suspension work, you’re likely looking at air-ride.

Drivers also notice it by feel. Air-ride rigs tend to ride smoother and sit more consistently under load, especially compared to stiff spring setups that transmit more impact.

Air-Ride Suspension And Load Weight

Air-ride suspension isn’t just about comfort. It’s also the reason pressure-based onboard weighing is possible.

As load weight increases, air spring pressure increases. That relationship is what allows fleets to estimate load weight from air suspension pressure. It’s practical because it gives drivers a way to check “am I close, am I heavy, am I balanced” without leaving the dock or guessing before a weigh station.

There’s an important boundary here. Air suspension pressure readings are not the same thing as a certified scale ticket. If you’re paid by weight or need legal-for-trade numbers, certified scales still matter.

But for daily operations, pressure-based weight visibility solves a different problem. It reduces surprise. It reduces wasted scale trips that are purely for peace of mind. It helps drivers make adjustments while they still have options.

The Before-You-Roll Workflow

The best time to catch an overweight or balance problem is at the shipper, not at the weigh station.

When a driver can see axle group weight and gross weight during loading, the workflow gets cleaner. You can spot issues early, adjust freight placement, and avoid the backtracking that costs time and creates tension with shippers.

It also helps with consistency across drivers. Instead of relying on “feel” or guesswork, the operation has a repeatable process: load, check, adjust, then roll.

Where BIT Air Scale Fits

Air-ride suspension pressure gives you a signal. But signal quality depends on resolution, calibration, and consistency. That’s where dedicated onboard systems matter.

BIT Air Scale is built to turn air suspension pressure into usable weight visibility inside the BIT platform. It’s designed for real-world loading workflows where drivers and admins want to know axle and gross weights before leaving the dock.

For fleets that scale loads constantly “just to be safe,” onboard weight visibility can reduce unnecessary scale trips and cut down overweight surprises. It also helps fleets keep better records of weight readings over time, which supports more consistent loading and fewer repeat problems.

This isn’t about replacing certified scales when certified weights are required. It’s about reducing guesswork, saving time, and running cleaner operations with fewer avoidable delays.

Bottom Line

Air-ride suspension replaces steel springs with air springs to create a smoother, more controlled ride and to keep trucks and trailers level under changing loads. It improves ride quality, protects freight, and helps operations stay consistent from load to load.

The tradeoff is maintenance. Air systems have more components, and small leaks or moisture issues can turn into downtime if they’re ignored. The fleets that get the most value out of air-ride treat it like a system worth maintaining, not a feature that runs forever without attention.

If your operation wants fewer surprises at the dock and fewer stressful moments at weigh stations, understanding air-ride is part of the job. And if you want more consistent weight visibility while loading, tools like BIT Air Scale fit naturally into the workflow.

Frequently Asked Questions

What Is An Air-Ride Suspension On A Semi Truck?

It’s a suspension system that uses air-filled rubber air springs instead of steel springs to support the truck and absorb road shock.

How Does Air-Ride Suspension Keep A Truck Level Under Different Loads?

It adds or releases air in the air springs to maintain a target ride height as load increases or decreases.

What Are The Main Parts Of An Air Suspension System?

Most systems include air springs, air supply, air lines, valves (including a leveling valve), and sometimes height sensors and electronic controls.

Is Air-Ride Better Than Leaf Spring Suspension For Trucking?

Air-ride is usually smoother and better for freight protection and comfort. Leaf springs are often simpler and cheaper to maintain. The best choice depends on how and where you operate.

What Causes Air-Ride Suspension To Sag Overnight?

A slow air leak is the most common cause. Leaks can come from air bags, lines, fittings, or valves.

What Is A Leveling Valve In An Air-Ride System?

It’s a valve that helps maintain ride height by controlling airflow into and out of the air springs as the suspension position changes.

Do Trailers Use Air-Ride Suspension Too?

Yes. Many freight trailers use air-ride to reduce vibration and help protect cargo, especially on long routes.

Can Air-Ride Suspension Help Reduce Scale Tickets Or Overweight Risk?

Air-ride pressure changes with load, which can support weight estimation and better load balancing before rolling. For more consistent weight visibility, fleets often use dedicated onboard scale tools during loading.