Air lines are a critical component of many commercial vehicles, including trailers with air brakes and air suspensions. These components help properly balance your loads and provide reliable and efficient stopping power. However, over time, the air lines that supply compressed air to these systems can deteriorate or become damaged, leading to performance issues, vehicle maintenance violations or even complete brake failure.

Damaged or poorly maintained air lines are some of the easiest vehicle maintenance issues that DOT can find during a level 1 inspection. Because of how easy it can be to find issues with the air system and air lines these violations can rack up points on your CSA score leading to higher insurance cost and DOT audits if not managed properly.

In this blog post, we will cover the process of identifying warning signs that indicate a problem and how to change air lines on your trucks and trailers equipped with air brakes and air suspension. We'll also discuss the necessary tools, and step-by-step instructions to ensure a successful air line replacement.

Signs of Air Line Issues:

Making sure that you train your drivers to catch signs or air leaks can help you reduce your maintenance cost by being able to fix these small issues before the cause more significant damage to your brakes or suspension components. Some of the signs that your air lines are starting to fail are:

- Reduced braking performance

- Air leaks or hissing sounds

- Excessive moisture in the air brake system

- Cracked, chafed, or damaged air lines

By training your drivers on how to look for these issues during pre-trip inspections and DVIR's and introducing these checks in your preventative maintenance program you can keep your equipment for having to go out-of-service for more costly repairs.

Tools You Will Need to Replace your Air Lines

- Safety gear: Protective eyewear, gloves, and steel-toed boots

- Wheel chocks

- Floor jack and jack stands (if necessary)

- Socket set and ratchet

- Wrench set

- Pliers

- Air line cutter or tubing cutter

- New air lines (with appropriate diameter and length)

- DOT Approved Push-to-connect fittings (if not included with the new air lines)

- Air line release tool (if applicable)

- Soapy water in a spray bottle

- Zip ties or appropriate fasteners

Steps to Changing Air Lines

-

Safety First: Begin by putting on your safety gear, including protective eyewear, gloves, and steel-toed boots. This will protect you from any debris or potential hazards while working on the air brake and air suspension systems.

-

Park and Secure the Trailer: Park the trailer on a level surface and engage the parking brake. Place wheel chocks in front of and behind the wheels to prevent any accidental movement.

-

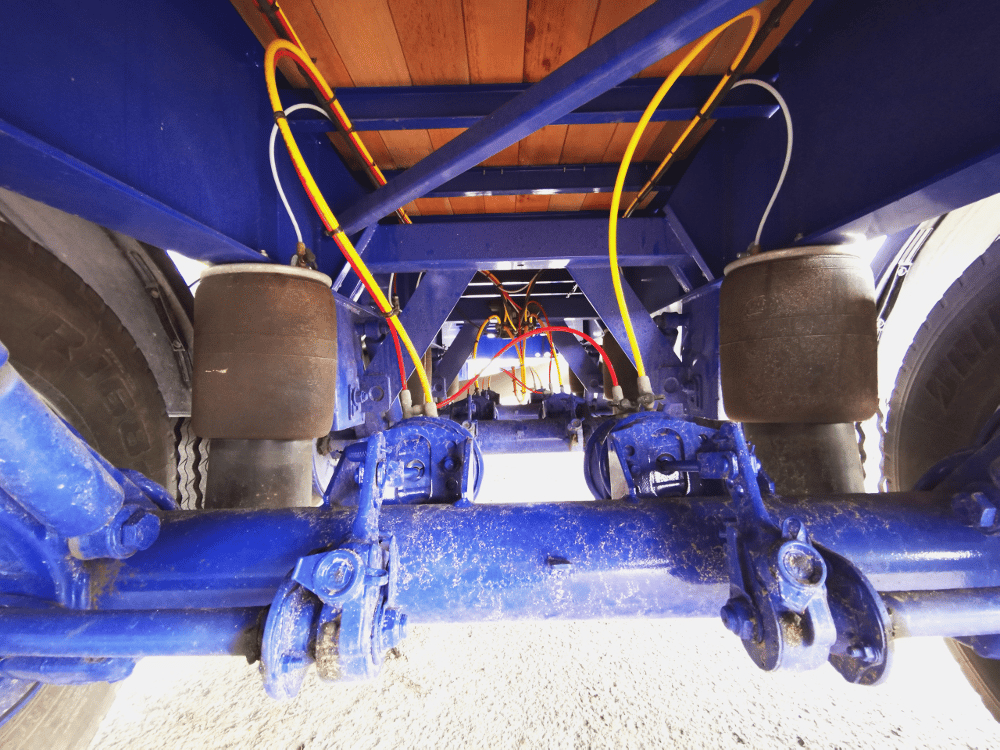

Locate and Inspect the Air Lines: Identify the damaged or worn air lines that need replacement by visually inspecting them for cracks, chafing, or other signs of wear. Additionally, listen for any hissing sounds or air leaks while the air system is pressurized.

-

Release Air Pressure: Before working on the air lines, release the air pressure from the air brake and air suspension systems. Locate the air tank drain valve(s) and open them to release the air. You may also need to activate the air suspension dump valve if your trailer is equipped with one.

-

Disconnect the Old Air Lines: Disconnect the air lines from the affected components, such as brake chambers, air suspension air bags, and air tanks. Use an air line release tool if required. If the trailer must be lifted for better access, use a floor jack and jack stands to safely raise and support it.

-

Cut and Measure the New Air Lines: Using an air line cutter or tubing cutter, cut the new air lines to the appropriate length. Make sure they are long enough to account for any bends and allow for proper routing.

-

Install the New Air Lines: Connect the new air lines to the appropriate components using push-to-connect fittings or the fittings provided with the new air lines. Ensure that the connections are secure and properly seated.

-

Secure the Air Lines: Route the new air lines in the same manner as the old ones, avoiding any sharp bends or areas where they may rub against other components. Secure the air lines with zip ties or appropriate fasteners to prevent movement and chafing.

-

Pressurize the System and Check for Leaks: Close the air tank drain valve(s) and start the towing vehicle to build air pressure in the system. Use a spray bottle filled with soapy water to check for any air leaks around the new air line connections and fittings. If you notice any bubbles or hissing sounds, tighten the connections or reseat the fittings as needed.

-

Test the Air Brakes and Air Suspension: With the air pressure restored, test the air brakes and air suspension for proper operation. Apply and release the brakes several times to ensure consistent performance. Also, verify that the air suspension inflates and deflates as expected.

-

Lower the Trailer (if lifted): If you raised the trailer earlier, carefully remove the jack stands and lower it using the floor jack.

-

Perform a Road Test: To ensure the successful installation of the new air lines and the proper functioning of the air brake and air suspension systems, take the trailer for a short test drive. Pay attention to the braking performance and ride quality. If you notice any issues, reinspect the air line installation and address any problems before continuing to use the trailer.

Changing the air lines on a trailer with air brakes and air suspensions is an essential maintenance task that ensures the safety and performance of your vehicle. By following these steps and taking the necessary precautions, you can successfully replace damaged or worn air lines and restore the functionality of your air brake and air suspension systems. Regular follow ups during pre-trip inspections and DVIR's can help extend their lifespan and prevent more serious issues down the road.